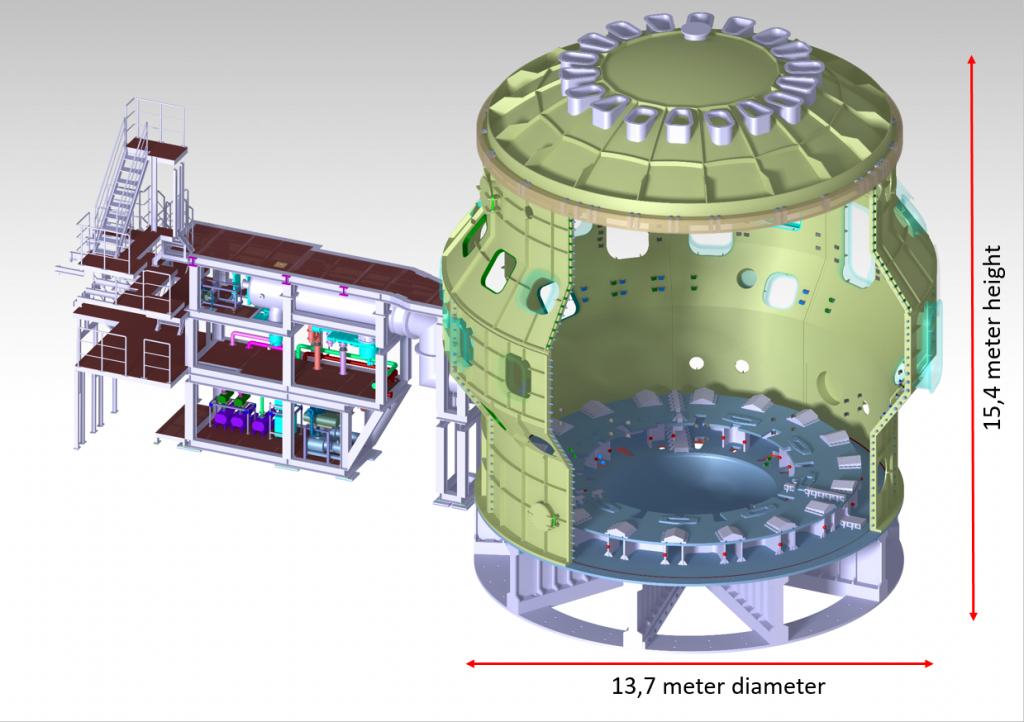

Tokamak – Cryostat

The main purpose of the cryostat is to provide a vacuum around the cold magnet components to minimise the thermal loads.

The body of the cryostat is a cylindrical structure about 14 m in diameter and 15.5 m high. The cryostat vessel is made of 30 mm single-walled stainless steel. The skin has a structure to support the weight of all the ports and port plugs and to withstand the vacuum pressure.

The top lid is shifted upwards to maximise the inner space for the assembly and maintenance of cryogenic devices and connections. It allows access for possible direct removal or reinstallation of the central solenoid, and also features a rupture disk to take care of any excessive overpressure.

Large numbers of ducts interconnect the VV ports with the corresponding penetrations in the cryostat vessel and also provide access for maintenance and inspection equipment, pumping, exhaust, in-cryostat feeders, etc. Bellows are integrated in the ducts to compensate for differential movements.

The cryostat base is designed as a robust structure to support the dead weight of superconducting magnets, thermal shield, and the vacuum vessel, including in-vessel components, as well as operational electromagnetic loads, thermal stress during baking, and standard operational conditions, accidental overpressure, and seismic loads.

CRYOSTAT with CRYO exhaust system