The central solenoid is the heart of the JT-60SA tokamak and is critical to initiate the plasma and then to drive current in it. Plasma current is a defining feature of a tokamak which substantially enhances the confinement of the superheated particles.

The central solenoid is wound from niobium tin (Nb3Sn) cable-in-conduit conductor (CICC), which in the absence of any magnetic field becomes superconducting at about 18 K (-255°C). Early on 22 July the four modules of the central solenoid reached this temperature and the resistance of the magnets dropped to almost zero, demonstrating that the central solenoid is superconducting.

The 18 toroidal field coils and 6 equilibrium field coils are made using niobium titanium (NbTi) CICC. Their superconducting transition occurs at about 9 K (-264°C), meaning that it took a couple more days to reach and could be observed on 24 July.

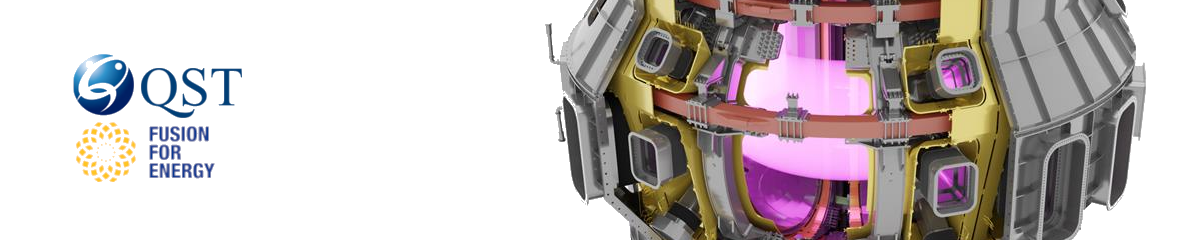

By allowing current to flow with no resistance (unlike a conventional electromagnet), the superconducting magnets of JT-60SA will allow plasmas to be produced for long durations without excessive power consumption. JT-60SA is the largest superconducting tokamak built so far. The largest magnet has a diameter of 12m.

Meanwhile the vacuum vessel that will contain the JT-60SA plasma continues to be ‘baked’ at an elevated temperature of 200°C in order to remove impurities attached to its surface.